با کیت شستشوی مدار گرمایش دوال واش دیگر نیاز به تعویض اب سیکل گرمایش را ندارید، پس بنابراین باعث میشود آب بادرصد سختی موقت کمتر و بدون اکسیژن از مدار گرمایش تخلیه نشود –

بازگشت راندمان حرارتی مدار گرمایش رابا استفاده از دوال واش تجربه خواهید کرد.

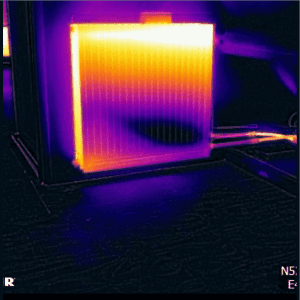

با وجود آهنربای بسیار قوی و مخزن بزرگ در کیت شستشوی دوال واش جداسازی رسوبات فلزی از مدارگرمایش به خوبی صورت میگیرد

47,500,000 تومان

یکی از مشکلات رایج در سیستم های گرمایشی و در مدار شوفاژ (را یاتور و یا فن کویل) وجود رسوبات فلزی در سیستم می باشد.

نتیجه وجود رسوب در مدار شوفاژ مشکلات زیر است:

همه مشکلات ذکر شده در بالا به علت وجود و حضور رسوبات فلزی از جمله مگنتایت (Fe3)4) و هماتیت (Fe2O3) در مسیر گرمایش می باشد.

لازم به ذکر است که شستشوی مدار شوفاژ و شستشوی رادیاتور پکیج با آب شهری کافی نمی باشد چرا که:

در نتیجه برای تمیز نمودن رسوبات فلزی باید با یک روش موثر تر اقدام به تمیز نمودن سیستم نمود.

توصیه پیاکو بریا شستشوی مدار گرمایش استفاده از کیت شستشوی مدار گرمایش می باشد که با این روش می توان حداقل ۸۰ درصد از رسوبات فلزی سیستم را تمیز نمود.

در این روش کافی است که با قراردادن کیت شستشوی مدار گرمایش، بدون نیاز به هیچ گونه اتصال یا تجهیز اضافی، کیت سشتشو را در مسیر برگشت گرمایش نصب نمود و مراحل زیر را به ترتیب اجرا نمود:

در پایان پس از تمیز نمودن آهنربا توسط پارچه و بستن آن در محل خود، اقدام به جدا نمودن کیت شستشو از سیستم می نماییم و پس از بستن مجدد اتصالات اولیه به پکیج شوفاژ دیواری، سیستم را آبگیر نموده و در حالت آماده به کار قرار می دهیم.

1- برای ایده آل ترین حالت و برداشتن تمام رسوب ها استفاده همزمان از کیت شستشو با تزریق ماده G3 بعنوان Cleaner توصیه می گردد چرا که باعث ۱۰۰ درصدی راندمان شستشو می شود. چون با روش ویبره نمی توان لوله کشی و مبدل ها را ویبره نمود و رسوبات محبوس در این دو قسمت توسط محلول جداسازی می گردد.

2- پس از شستشوی سیستم و برگرداندن سیستم شوفاژ به حالت اولین روز نصب، تزریق محلول محافظ مدار گرمایش G1 استفاده شود که از ایجاد رسوب فلزی و آهکی در مدار گرمایش، جلوگیری کند.

3- نصب فیلتر مغناطیسی، بر روی دستگاه های پکیج برای جلوگیری از خرابی قطعات پکیج شوفاژ دیواری به شدت توصیه می گردد.

کیت شستشوی مدار گرمایش dual wash وسیله ای ایده آل برای شستشوی کامل مدار گرمایش(شوفاژ) می باشد:

محصول دوال واش مناسب سیستم های با حجم رسوبات فلزی بالا که به صورت کلونی در رادیاتور ها وجود دارند، به جهت پاکسازی کامل سیستم پکیج و رادیاتور، بدون نیاز به باز کردن قطعات کاربرد دارد.

با اتصال این محصول در مسیر برگشت گرمایش پکیج و ویبره کردن رادیاتور ها با محصول ویبرامکس، کلیه رسوبات فلزی که در سیکل بسته گرمایش به صورت کلونی تجمع پیدا کرده اند، جدا شده و از سیستم خارج شوند.

این محصول ابزار کار تکنسین بوده و به صورت دائم بر روی دستگاه نصب نمیشود.

بیشتر کاربرد این محصول برای همکاران تکنسین می باشد.

دوال واش را روی مسیر برگشت پکیج نصب کنید تا در زمان تقریبی 90 دقیقه راندمان حرارتی سیستم را به روز اول برگردانید. ابتدا دو شلنگ شفاف همراه را با استفاده از دو واشر تخت و بست فلنجی به مخزن دوال واش متصل کنید و سپس یک سر شلنگ به برگشت گرمایش از دیوار و سر دیگر به برگشت گرمایش زیر پکیج متصل شود. دستگاه پکیج را آبگیری و در حین آبگیری و قرار دادن فشار دستگاه روی 1.5 بار، پیچ هواگیر روی مخزن دوال واش را باز کنید تا هوای سیستم به طور کامل از بالای مخزن دوال واش تخلیه گردد. پکیج را روشن کنید. تمام رادیاتور هارا از قسمت رفت و برگشت بجز یک رادیاتور ببندید و با استفاده از ویبرامکس (چکش لرزه ای) که همراه کیت شستشو ی مدار گرمایش دوال واش می باشد، به مدت 30 ثانیه ویبره کنید. به همین ترتیب تمام رادیاتور هارا یک به یک باز و رادیاتور ویبره شده را می بندیم. در نهایت وقتی تمام رادیاتور ها را یکبار ویبره کردید، تمام آن هارا باز میکنیم تا هر دو شلنگ دوال واش سفید شود و سیستم عاری از رسوبات مگنتایت گردد.

بعد از اتمام کار شیر ورود و خروج دوال واش را ببندید و پیچ هواگیر را باز کنید تا فشار از روی مخزن محصول برداشته و درب آن را باز با آچار مخصوص باز کنید. سپس شفت مغناطیسی را با یک پارچه تمیز کنید. کیت را از پکیج جدا و اتصالات مربوط به پکیج را مجدد ببندبد و دستگاه را راه اندازی کنید.

نکته: محصول ویبرامکس فقط به سر دریل پیکوری (ضربه زن) نصب و قابل استفاده می باشد. باید توجه داشته باشید هرگز به صورت چرخشی استفاده نگردد.

| Weight | 7.71 kg |

|---|---|

| Dimensions | 42 × 22 × 25 cm |

| مورد مصرف | به عنوان ابزار کار تکنسین و سرویسکار سیستم های سرمایشی و گرمایشی با هدف شستشوی کامل مدار بسته سرمایش و یا گرمایش |

| محاسن کاربرد | نصب و کاربری آسان حین استفاده |

| جنس | استیل ضد زنگ |

| محل نصب | در مسیر برگشت مدار گرمایش حین شستشوی سیستم |

| سایز اتصال | G3/4" |

| قدرت میدان مغناطیسی | ۱۲۰۰۰ گاوس |

| گارانتی بی قید وشرط | ۵ سال |

| شرکت سازنده | پیاکو |

| کشور سازنده | ایران |

| محتویات داخل محصول | کیت شستشوی dual wash |

از Belnet برای شسشتوی سیکل تبرید تمامی سیکل های تراکمی کوچک از جمله یخچال کولر خودرو، کولر گازی پنجره ای و اسپلیت ومینی چیلر ها می توان استفاده کرد.

خیر، این محصول به هیچ دستگاه یا اتصالی برای استفاده ندارد و کپسول آماده استفاده است.

برای شستشوی کامل سیکل تبرید به منظور پاک سازی رسوبات داخل سیستم و پاک نمودن روغن های باقی مانده بر جداره ها می توان از کپسول شستشوی سیکل تبرید Belnet استفاده نمود.

به کمک Belnet می توان در تمامی طول مسیر سیکل شستشو را انجام داد و پس از استفاده از آن نیازی به آب کشی یا هیچ کار اضافه ای نیست ولی در روش سنتی هم نمی توان به صورت کامل سیستم را شستشو داد و هم ریسک حضور اکسیژن در سیستم بالا خواهد بود.

پس از شستشوی سیستم با Belnet نیاز به هیچ کار اضافه ای نیست و پس از زمان کوتاه برای تبخیر آن در سیکل سیستم آماده گاز گیزی مجدد می باشد.

هیچ محصولی مشابه این محصول از سمت پیاکو توصیه نشده است.

8 reviews for کیت شستشوی مدار گرمایش (Dual Wash)

فرزین عاشوری –

باسلام کارکردش عالیه

ابراهیم شیخی –

دستگاه بسیارعالی وکارایش حرف نداره من که خیلی ازش راضی هستم و قابل مقایسه با روش سنتی نیست

ابراهیم شیخی –

دستگاه بسیارعالی وکارایش حرف نداره من که خیلی ازش راضی هستم و قابل مقایسه با روش سنتی نیست۱۰۰

سیدمحمد سعیدی (verified owner) –

وافعا عالیه…من تستش کردم اول با روش سنتی دستگاه رو شستشو دادم و سپس این دستگاه رو متصل کردم …بعد از شستشو با این دستگاه کلی ذرات مگنتایت و لجن رو جذب کرده بود…به هیچ وجه نمی شه با روش سنتی سیستم رو اینجوری فلش کرد

سعید رضائی پور –

تا الان امتحانش نکردم، ولی در صورت امتحان حتما نظرم رو اعلام میکنم.

مصطفی معتمدی –

قیمتش تخفیف نمیخوره؟!

حسن سیدی –

با روش سنتی کلیه رسوبات خارج نمیشه ولی با این دستگاه عالیه

سیدمجتبی نبوی –

دستگاه خوبی.اگر می شود. برای ابگرمکن دیوار استفاده می شود. خیلی بهتر بود